The driving pile is be done at the place far from residents’ zone, suitable for river area and for coastal area, deep sea area, therefore the preparation works before driving pile as below:

· Study the soil investigation and the geological-hydrological, thickness and specification soil layers.

· Investigation whether has obstacles underneath ground level to find the solution remove if there is an underground structure and adjacent projects in order to mitigate an impact its.

· To consider the urban environmental conditions (noise and vibration) regarding to requirement of environment’s specification where is adjacent residents’ zone and other projects.

· Take over the plan layout to construction.

· Setting up the grid lines to determine location of foundations and co-ordinates of piles where to driving on layout.

· Checking the Certificate Original of pile (if pile is purchasing or make at factory).

· Checking actual dimensions of pile (comply with regulations).

· Transfer and arrange piles on layout.

· Remark on segments of length pile.

· Combine segments to comply with design of the length piles.

· Setting up the theodolite to check the vertical direction and the refusal of pile.

The pile to be driving RC piles to achieve compressive strength comply with specification of project. The contractor must be ordered enough quantity pile to continuously for driving pile. The pile to be arranged layer by layer ensure that it doesn’t have any curved, warping or cracked/ broken by its self-weight, convenient to lift it up then need to insert the wooden spacer.

1. Driving RC pile

· Installation of the hanger of hammer, the route motion of hammer at centralize adjustment the hammer on vertical direction and balance itself.

· The Total station or theodolite at fixed location to check vertical or incline of pile.

· Driving pile inland to be use crawler crane to arrange pile on ground level after that lift it from ground up to vertical direction and move pile inside hanger of hammer at exactly location to make sure that central’s pile at the design grid line.

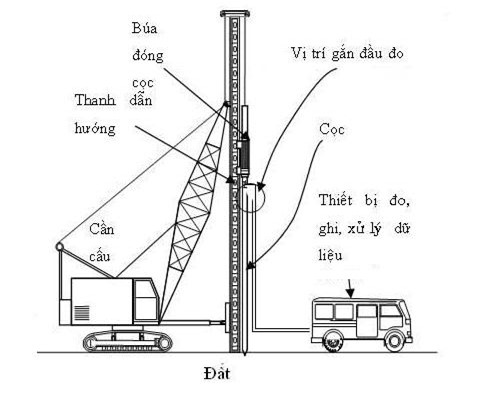

Driving PHC, RC pile onshore jobsite (vertical driving)

Equipment and tools for driving pile

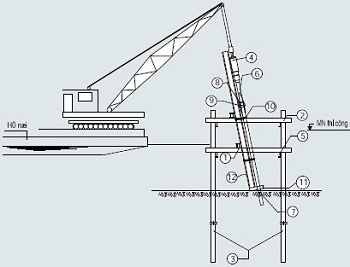

· Driving pile in water zone: fixed barge, adjust the equipment to sure that the incline direction as design, to fit the pile into hanger of hammer and adjust pile to location as well as the grid line of pile coincide with central of hammer in order to hanger of hammer can be hold pile and the central of pile is correct direction of design direction.

Offshore driving inclined pile

Driving incline pile in water zone.

Because the self-weight of hammer makes the pile sink down a part of pile. Checking by theodolite before driving a few knocks in order to the pile fix to ground and hold on to check the stabilize of pile, hammer, hanger after that turn on hammer continue to be driving pile.

In the process driving pile, technician must be often checking pile and settlement at real time to determine the refusal of pile.

The refusal of driving pile is the average settlement of pile for one knock of hammer (to record the refusal of vibration hammer is record in 1 minute).

· For pile to support structure above, driving must be fixed into design level.

· For pile get friction around pile body, driving must be achieved the design of refusal.

To be driving pile to achieve design level must be applied the conducting steel 2 pieces of I-350 pipe 4-5m long, to avoid the shock force on head of pile it must be inserted wooden blank and hemp sacks.

Denotes that the weak layer underneath with thick layer to avoid lost by sinking pile.

2. DRIVING TRIAL PILE (TEST PILE):

· Before driving the mass pile must be done driving trial pile (test pile) within enough quantity required on design regulations to determine the length of pile depending on each zone of project.

· To use dark paint, make the level line to measure the length, at head of pile must be divided more level lines to easy measure and checking. The driving test pile is includes 2 stages: first driving pile to achieve design level or achieve the design refusal, second driving to inspection capacity of pile.

2.1. Driving for first stage (to achieve design level or achieve the design refusal)

- To control the diesel hammer works as sequences above and record quantity the hammer knocks down to pile per driven meter, specially the last 1m on top must be record the average refusal for 1 knock of hammer (cm/minute).

- In case, the pile doesn’t approach design level regarding to this technical issue then the driving pile should be suspended driving around 7 days. After then, re-driving until to achieve the design refusal and report to Design Consultant, Supervisory Consultant to have the solution to extension length of pile or need to be postponed 7 days more to re-check whether the driving pile achieve design refusal or must be treated by other solution.

2.2. Driving to inspect capacity of pile.

- After driving pile spend 7 days, using diesel hammer to knock on pile, measure the refusal and measure the falling height’s piston of hammer. If pile has been achieving the design refusal the sequence of driving test pile to stop. Otherwise, the refusal doesn’t achieve then all these activities must be report to Design Consultant and Supervisory Consultant to suggest the treatment.

3. DRIVING MASS PILE:

After got the result of trail pile (Test pile), process to be driving mass piles following the sequence driving incline pile first and straight pile later. The method of statement driving mass pile as same as driving trail pile, there one different is driving until pile achieve the refusal, it means non-stop on the sequence driving. During driving process must be closely supervised and record in the history of pile and treatment record if have. There are some notes during driving as below:

· Always checking the position of boom, location of pile and take a look the condition of head pile, body of pile. There is any damaged by material need to be record on history of pile immediately to replace the new one. In case the head of pile was been damaged for many piles and inspect case by case of each damage, it is doesn’t caused by disqualify material need to consider the technical of driving and the length of pile fixed into ground.

- The first knocks of diesel hammer has the piston falling down doesn’t access 0.5 meter, but the next knocks of diesel hammer is ascending upto maximum falling height of piston requires for hanging diesel hammer in the history of hammer. Apply for hanging free-fall piston, the height to lift up must be corresponded self-weight of hammer, pile of dimension and material, and soil condition.

4. WELDING WORKS:

Comply with TCVN 9394:2012 requirements:

The constrain to welding to connect segments pile as below:

· Dimensions of steel plate must be complied with design.

· The grid of pile must be checked vertically for 2 directions that perpendicular together.

· The surface of two segments must be plate and there is no gap between them.

The welding line must be sured to comply with regulations of design regards to forces, there is not allow any defects as below:

· Dimensions had tolerance with design requirements.

· The height or the width of welding lines doesn’t equivalence.

· The welding line doesn’t straight, surface has bubble, doesn’t enough temperature to burn steel elements at both sides, overheat, flown welding, slag inside welding line, cracked line, etc.

The sequence of driving pile to be continued after check there not a defect as above.

5. HISTORY OF PILE ON INSPECTION DOCUMENTS

· History of pile need to record these data as below:

· casting date, driving date.

· Segment No, location and dimension of pile.

· driving level, quantity of segments and connection between segments.

· Type of hammer, the falling down’s piston of hammer, quantity knock of hammer/ minute.

· The quantity of knocks to be driving pile go down 100cm.

· The quantity of knocks to be driving pile go down for last 20cm.

· Typical of cushion on head of pile.

· Sequence driving pile in the group of pile.

· Technical issues taken place to suspend the driving pile and tolerance.

· Name of supervisor and Team leader.

In the history of pile must be recorded quantity knocks of hammer for 1m sinking and each 20cm for last 3m of pile.